Tile Glaze 101

At Heath, we create all of our glazes according to proprietary recipes – just as Edith did back when we started. That means we’ve had over 50 years experience in it, and have learned a thing or a hundred about what works — and what doesn’t — when it comes to glaze.

We’re always working on our glazes, whether it's creating new glazes, or reformulating existing ones, and it takes a village to do so. The joy of being a vertically-integrated company (where we design, make, and sell our own products) means that we have all the skills we need under one roof, and have long experience at working together. Our design teams work closely with our glaze masters, ceramic engineering and production teams to create and refine our glazes. It's a long, laborious process involving numerous steps and constant testing.

Glaze is made up of a number of minerals and metals that define color, opacity, and finish. It’s the result of a chemical interaction between these mineral ingredients, which include silica, flux, and clay — and fire where each ingredient undergoes a molecular reaction under high heat. Glaze chemistry and firing are not precise: ceramic engineers use a mix of knowledge of chemistry, analysis, experience, and multiple trials to get is as close to a science as possible. So the next time you ask if that matte yellow can be done in a glossy glaze, the answer is likely “no”. Changing the finish will likely affect the color.

The basic recipe is a combination of silica, flux, and clay. Each category of ingredients provides and controls certain characteristics.

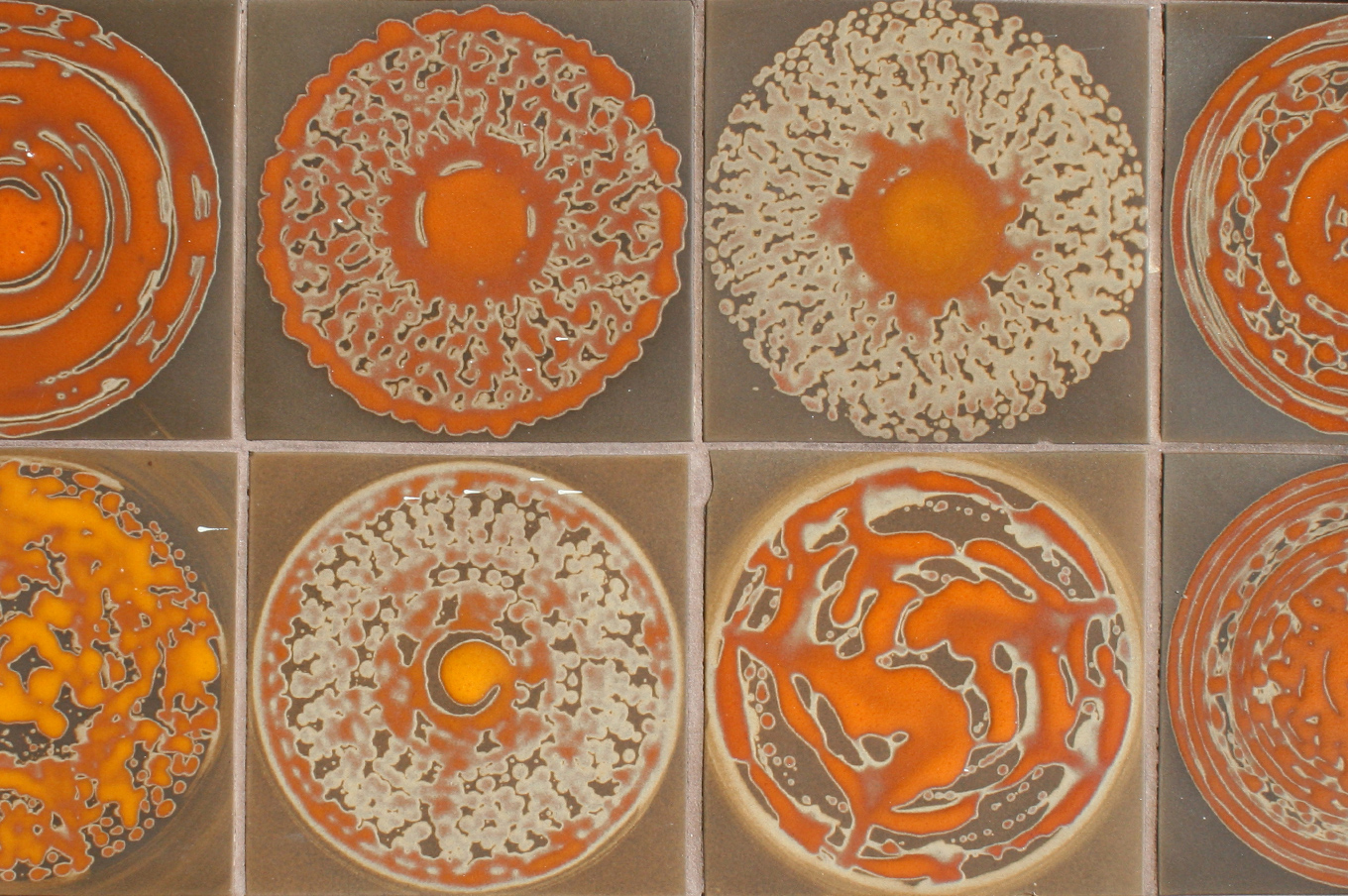

Silica is like sand, and provides a glossy, glassy finish. Flux is a category of glass-forming materials, and lowers the overall melting point of a glaze, enabling a melting or flowing visual effect in glaze. Clay used in glazes often comes from kaolin, which is a type of porcelain clay; other materials include pumice, feldspar, iron oxide, manganese, copper oxide, and ball clay. The ratios of these ingredients vary depending on desired results.

Even though we control the formula, specify the ingredients, and work with suppliers we know, the materials we use can vary tremendously over time — which is why we’re often working to completely reformulate, or at least “tweak” the glazes we have. Cobalt, for example, will vary depending on what part of a given mine it’s coming from, while copper will oxidize over time, creating significant variation in our glazes.

We receive some of the materials in a pre-blended form in order to maximize consistency: stains and frits are mixtures of raw materials that have been fired once, then ground back into a powder in order to stabilize some natural materials. With standardized batches, greater consistency is possible, and some of the less friendly materials are safer for employees who handle them in powder form.

Some stains are highly concentrated, while others have a low potency: this range means that there’s a huge number possible results from them. Bases are used to control physical and visual characteristics, such as finish — matte, glossy, frost-glossy, satin-matte, and crackle (only used for tile). Once a base has been selected, stains and other natural materials are added to create color.

You can achieve a more uniform look with “waterfall” glaze lines (used, typically, for high volume ceramic tile for sale at big-box home improvement stores). But we believe in the importance of the hand in creating our glazes, and because we know the outcome will be far more beautiful to anything produced on a high-volume, mass produced basis.

The final part of the glaze story takes place in the kiln, during the firing process, when materials melt, mature, and heal themselves into a glassy structure. We fire our kilns up to 2,080 degrees Fahrenheit over an eight hour firing. The firing process is when the glaze gets its color and surface finish. It’s also when anything can happen and dictates whether our tile is bound for a happy client, our seconds shed, a mosaics class, to be used as “grog"... or perhaps as the inspiration for our next glaze, the result of a happy accident. It’s all in a day’s work at Heath.

— Emily Holmes (thanks to Ada Ko and Rosalie Wild, too!)

Header photo: Mark Allen Johnson